- Home page

- About Us

About Us

-

The Aiser poultry farm is a high-tech enterprise with a well-coordinated mechanism and strict control at all stages of production. The likelihood of epidemics and bird diseases (such as "bird flu") is reduced to zero. Daily monitoring of the broiler flock is conducted, and a set of measures has been developed to prevent infectious diseases. The perimeter of the poultry farm is guarded, production discipline is observed, and sanitary checkpoints and disinfectant barriers are equipped.

-

The veterinary service of the enterprise conducts extensive preventive work. Safety measures include disinfection of the territory and premises, vaccination, and adherence to zoohygiene rules.

-

The poultry farm's laboratory monitors the broilers' diet composition and controls the quality of the produced products.

-

-

rearing shops

-

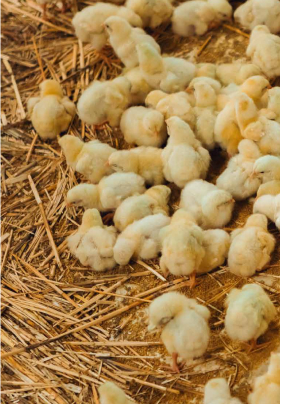

Incubator

Egg laying, hatching on the 21st day

-

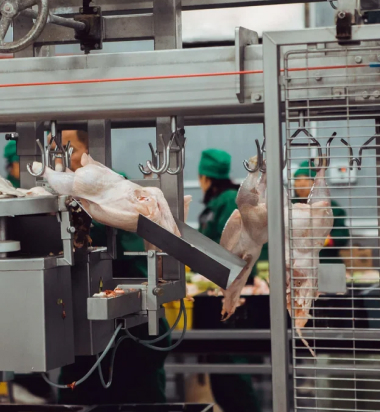

Slaughterhouse

- • Slaughtering,

- • Scalding,

- • Plucking,

- • Butchering,

- • Packing

-

-

-

parent stock shops

-

Broiler shops

Growing — 39/40 days

-

Finished product warehouse

Release of finished products for sale

-

-

Incubator

Capacity — 20 million chicks per year Equipment supplier: Petersime, Belgium

Our poultry farm uses the most reliable and proven broiler cross in the world — ROSS-308. This cross allows you to grow a bird of ideal size in 40 days. The breed is characterized by absolutely white plumage, a massive breast, and an attractive carcass color (not too white and not too yellow) for consumers.

-

Feed mill Capacity

20 tons of pelleted feed per hour Equipment supplier: Tekhnex, Russia

72 Broiler shops

Capacity of one shop — 50,000 chicks Equipment supplier: VDL Agrotech, Netherlands

-

Slaughterhouse

We are always ready to supply both the freshest chilled products and essential frozen chicken.

FOR THIS, WE HAVE:

Zero-temperature chambers and shock freezing chambers